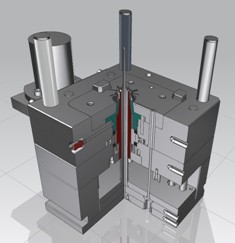

Defines component standard type for American and Canada injection mold tooling market

1) All mold components will adopt DME, Progressive, PCS, Parker, Balluff, and National only as listed by type below. Standard components will NOT BE ALTERED from the Vendor without special instructions for and documentation to the Customer.

2) Standard mold component types are as follows:

-Leader pins--------------------------------DME “GL” type (hardened and precision ground) or Class “S” Thomson Shafting

-Bushings-----------------------------------DME “LBB” type (bronze plated and precision ground)

-Guided ejection leader pins-------------DME “PF” or “GL” type or Class “S” Thomson Shafting

-Guided ejection bushings--------------- DME “GEB” type (bronze plated and precision ground)

-Locating rings-----------------------------DME “6521” OR “6522” (VARIABLE DEPENDING ON MOLD DESIGN)

-Sprue bushings----------------------------DME “B” or “U” series

-Three plate bushings----------------------DME “TEB” type

-Wear Plates--------------------------------DME “WPB” type (bronze plated)

-Angle pins--------------------------------- DME “APD” type, MDE “EX” ejector pins, or Class “S” Thomson Shafting, or DME “GL” type leader pins

-Mold and Die springs-------------------- DME / Raymond type (blue, red, gold)

-Parting line locks------------------------- Progressive Top Lock “TL” type

-Bar locks-----------------------------------DME tapered interlocks (rectangular)

-PKO extensions----------------------------Progressive Hex series or puck style

-Recycling and mold dating inserts------DME, PCS, or Progressive

-Ejector pins--------------------------------DME “EX” type

-Ejector sleeves-----------------------------DME “S” type

-Ejector Blades------------------------------National “Shank and Blade” type

-Air poppet valves--------------------------National or PCS

-Accelerated ejectors-----------------------PCS / Cumsa (patented, round) type

-Stop buttons---------------------------------PCS “SP” type

-Hydraulic Cylinders-----------------------Parker series 2H

-Limit switches (ejector plates)-----------DME “Thinswitch”

-Limit Switches (cylinder)-----------------Parker “EPS” style (mounted directly to cylinder)

-Limit Switches (other)--------------------Balluff Series F 60 Mechanical

3) Off-set (“zero”) Corners on all mold plates will have a .50” x 45-degree chamfer along the entire edge.

4) One leader pin and one return on off-set corner are to be off-set a minimum of 0.125” to

0.25” to prevent rotation of mold plates during assembly/disassembly.

Injection Mold slide lifter standards

Injection Mold runner standards

Injection Mold cooling standards

Injection Mold venting standards

Injection Mold Ejector System standards standards

Injection Mold component standards

Injection Mold Hydraulic and Pneumatic standards

Injection Mold Design Check standards

Injection Mold Steel Grades standards

Injection Mold inspection standards