Definition

The racetrack effect occurs when flow races through thick sections of the cavity before

the thin sections have filled.

Note: Thick sections offer less resistance to flow than thin sections.

Racetrack Effect

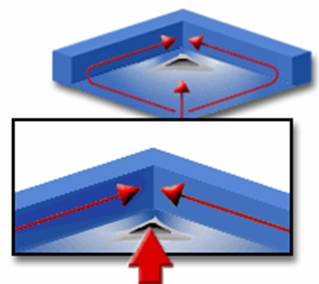

The racetrack effect indicates unbalanced flow paths and can often cause unnecessary weld lines and

air traps. The following diagram shows a part with a thick rim.

The flow of plastic (red arrows) races around the rim trapping a pocket of air (blue circle).

What to do

A large difference in wall thickness throughout a part can cause problems, but is sometimes necessary

from a design point of view. However, in the previous example, the racetrack effect through the thick regions is not actually the

problem. The problem is unbalanced flow that allows the racetrack effect to occur. If the plastic reached all parts of the thick rim

at the same time, the racetrack effect would not occur.

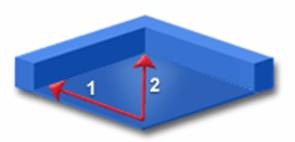

Flow path 1 is shorter than flow path 2. However, by slightly thickening flow path 2 or thinning flow

path 1 (see flow leaders and deflectors), the plastic could be forced to reach all parts of the thick rim at the same time. This would

result in balanced flows.

The above example of racetrack in a symmetrical part with a thick rim is often easy to solve.

In more complicated parts, thick walls may need some thinning, the polymer injection location may need to be altered, or multiple

polymer injection locations may need to be used.

Injection Molding air trap issue and solution

Injection Molding brittleness issue and solution

Injection Molding burn issue and solution

Injection Molding crack issue and solution

Injection Molding delamination issue and solution

Injection Molding dimensional variation issue and solution

Injection Molding discoloration issue and solution

Injection Molding excessive part weight issue and solution

Injection Molding fish eye issue and solution

Injection Molding flash issue and solution

Injection Molding follow line issue and solution

Injection Molding hesitation issue and solution

Injection Molding high volumetric shrinkage issue and solution

Injection Molding jetting issue and solution

Injection Molding overpacking issue and solution

Injection Molding racetrack effect issue and solution

Injection Molding short shot issue and solution

Injection Molding sink mark and void issue and solution

Injection Molding unbalanced flow issue and solution

Injection Molding underflow issue and solution

Injection Molding warpage issue and solution

Injection Molding weld and meld line issue and solution