Definition

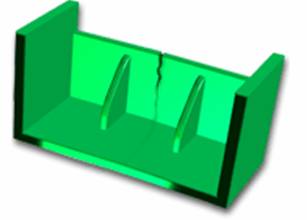

Cracking can cause part failure, a short part life and be visually unacceptable.

Cracks may not be obvious until several days or weeks after production. Hence, it is better to recognize

and remove the potential problem of cracking before production. Moldflow Plastics Insight provides detailed shear stress results.

Causes

High residual stresses

Cracks may occur in regions where internal shear stresses are frozen into the part.

Weld line weaknesses

Differential shrinkage

Differential orientation, packing and cooling cause differential shrinkage resulting in high

internal stress levels being frozen in.

Remedies

Minimize residual stress

Program the ram speed or increase wall thickness to reduce flow induced stresses. Check for the

recommended maximum shear stress value for the material (recorded in the Materials Database)

Minimize differential shrinkage

Solving one problem can often introduce other problems to the injection molding process.

Each option hence requires consideration of all relevant aspects of the mold design specification.

Injection Molding air trap issue and solution

Injection Molding brittleness issue and solution

Injection Molding burn issue and solution

Injection Molding crack issue and solution

Injection Molding delamination issue and solution

Injection Molding dimensional variation issue and solution

Injection Molding discoloration issue and solution

Injection Molding excessive part weight issue and solution

Injection Molding fish eye issue and solution

Injection Molding flash issue and solution

Injection Molding follow line issue and solution

Injection Molding hesitation issue and solution

Injection Molding high volumetric shrinkage issue and solution

Injection Molding jetting issue and solution

Injection Molding overpacking issue and solution

Injection Molding racetrack effect issue and solution

Injection Molding short shot issue and solution

Injection Molding sink mark and void issue and solution

Injection Molding unbalanced flow issue and solution

Injection Molding underflow issue and solution

Injection Molding warpage issue and solution

Injection Molding weld and meld line issue and solution