Definition

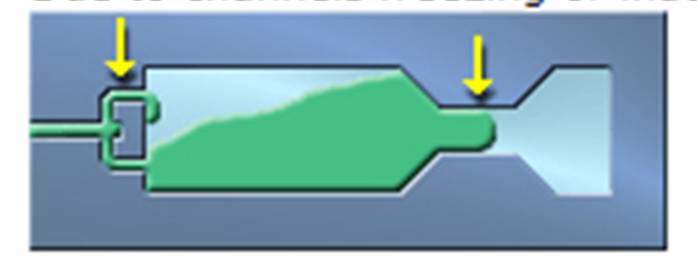

A short shot is the incomplete filling of a mold cavity which results in the production of an incomplete

part. If a part short shots, the plastic does not fill the cavity. The flow freezes off before all of the flow paths have filled.

To ensure the finished part is of good quality, the part must also be adequately packed with plastic.

Therefore the question to ask is not only, 'Will the part fill?', but, 'Can a good quality part be made?'

Causes

Flow restrictions

Due to channels freezing or inadequate runner design.

Hesitation and long or complex flow paths

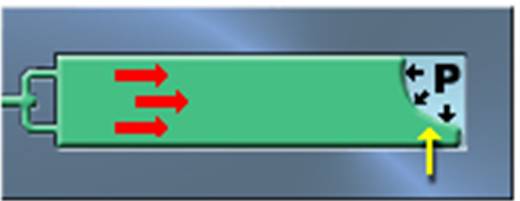

Inadequate venting

Back pressure due to unvented air traps can cause a short shot.

Low melt and/or mold temperatures

Insufficient material entering the cavity

An undersized machine, low shot volume, or inadequate ram speed.

Machine defects

Including an empty hopper, blocked feed throat, or a worn non-return

(check) valve that causes loss of pressure or volume leakage.

Remedies

Before you try one of the methods listed below, check all of the other results, so that you know

the exact cause of the short shot.

Avoid hesitation

Eliminate air traps

If air traps do exist, they should be positioned in regions that can be easily vented or ejection

pins added so that air can be removed.

Increase mold & melt temperature

This will decrease the viscosity of the melt, making it easier to flow through the part.

Increase ram speed

This can cause greater shear heating, which can decrease the viscosity of the melt, making it easier

to flow through the part.

Change part geometry

Balance flow paths so they fill in an equal time and an equal pressure. You may need to thicken

thin sections, or reduce the complexity of a flow path.

Change material

Select a less viscous material (higher melt flow rate). By choosing a material with a higher melt

flow rate, less injection pressure will be required to fill the part.

Increase the maximum injection pressure for this part

Solving one problem can often introduce other problems to the injection molding process.

Each option hence requires consideration of all relevant aspects of the mold design

Injection Molding air trap issue and solution

Injection Molding brittleness issue and solution

Injection Molding burn issue and solution

Injection Molding crack issue and solution

Injection Molding delamination issue and solution

Injection Molding dimensional variation issue and solution

Injection Molding discoloration issue and solution

Injection Molding excessive part weight issue and solution

Injection Molding fish eye issue and solution

Injection Molding flash issue and solution

Injection Molding follow line issue and solution

Injection Molding hesitation issue and solution

Injection Molding high volumetric shrinkage issue and solution

Injection Molding jetting issue and solution

Injection Molding overpacking issue and solution

Injection Molding racetrack effect issue and solution

Injection Molding short shot issue and solution

Injection Molding sink mark and void issue and solution

Injection Molding unbalanced flow issue and solution

Injection Molding underflow issue and solution

Injection Molding warpage issue and solution

Injection Molding weld and meld line issue and solution