Injection Molding defect:molding air trap

All Injection molding defects>Solving molding air trap problemsDefinition

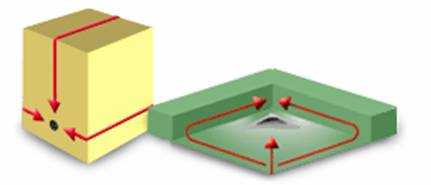

Air traps occur when converging flow fronts surround and trap a bubble of air. The trapped air can cause incomplete filling and packing, and will often cause a surface blemish in the final part. Air trapped in pockets may compress, heat up and cause burn marks.

Causes

Racetrack effect

Hesitation

Unbalanced flow paths

Flow paths do not need the racetrack effect or hesitation to have unbalanced flow. In a part with uniform thickness, the physical length of flow paths may vary, and again air traps may occur.

Inadequate venting

Lack of vents or undersized vents in these last-to-fill areas are a common cause of air traps.

Remedies

Balance flow paths

Avoid hesitation and racetrack effects

Balance runners

Changing the runner system can alter the filling pattern in such a way that the last-to-fill areas

are located at the proper venting locations.

Vent appropriately

If air traps do exist, they should be positioned in regions that can be easily vented or ejection

and/or vent pins added so that air can be removed.

Solving one problem can often introduce other problems to the injection molding process. Each option

hence requires consideration of all relevant aspects of the mold design specification.

Injection Molding air trap issue and solution

Injection Molding brittleness issue and solution

Injection Molding burn issue and solution

Injection Molding crack issue and solution

Injection Molding delamination issue and solution

Injection Molding dimensional variation issue and solution

Injection Molding discoloration issue and solution

Injection Molding excessive part weight issue and solution

Injection Molding fish eye issue and solution

Injection Molding flash issue and solution

Injection Molding follow line issue and solution

Injection Molding hesitation issue and solution

Injection Molding high volumetric shrinkage issue and solution

Injection Molding jetting issue and solution

Injection Molding overpacking issue and solution

Injection Molding racetrack effect issue and solution

Injection Molding short shot issue and solution

Injection Molding sink mark and void issue and solution

Injection Molding unbalanced flow issue and solution

Injection Molding underflow issue and solution

Injection Molding warpage issue and solution

Injection Molding weld and meld line issue and solution