Viewmold company provides custom plastic and metal parts,our company founded in Shenzhen, China in 1999, and is an ISO 9001:2000 certified plastic molding and metal machining manufacturer.

Our company has our own factory of 8,000 square meters and 100 sets precise machines. The total amount of investment in fixed assets has reached US$5 million. Our engineer team use advanced software for

Auto CAD, UG, ProE and Moldflow.

We currently employ 100 skilled and experienced staff members to work in engineering, production, inspection, all manufacturing are ensured with high standard process.

We have engaged in plastic molding and metal machining area for 20 years, and has complete quality management system, our QC engineers follow our quality procedures to ensure that all jobs are done right every time.

so our team can provide customers perfect parts and reliable services. Our Quality Assurance is your Quality Insurance, if you have any project that need plastic or metal parts, could you please contact us.

Our quotation engineers have rich experience for plastic molding and metal machining, they will provide you professional suggestion and help you save time and cost, and make your project success. Our company's plastic molding services

include:

injection molding. Our company has 30 injection molding machines from 120 ton to 1000 ton, and includes 2 sets double injection molding

machines, our injection molding services include injection molding, spraying, printing and package. our injection molding parts are perfect, precise, reliable.

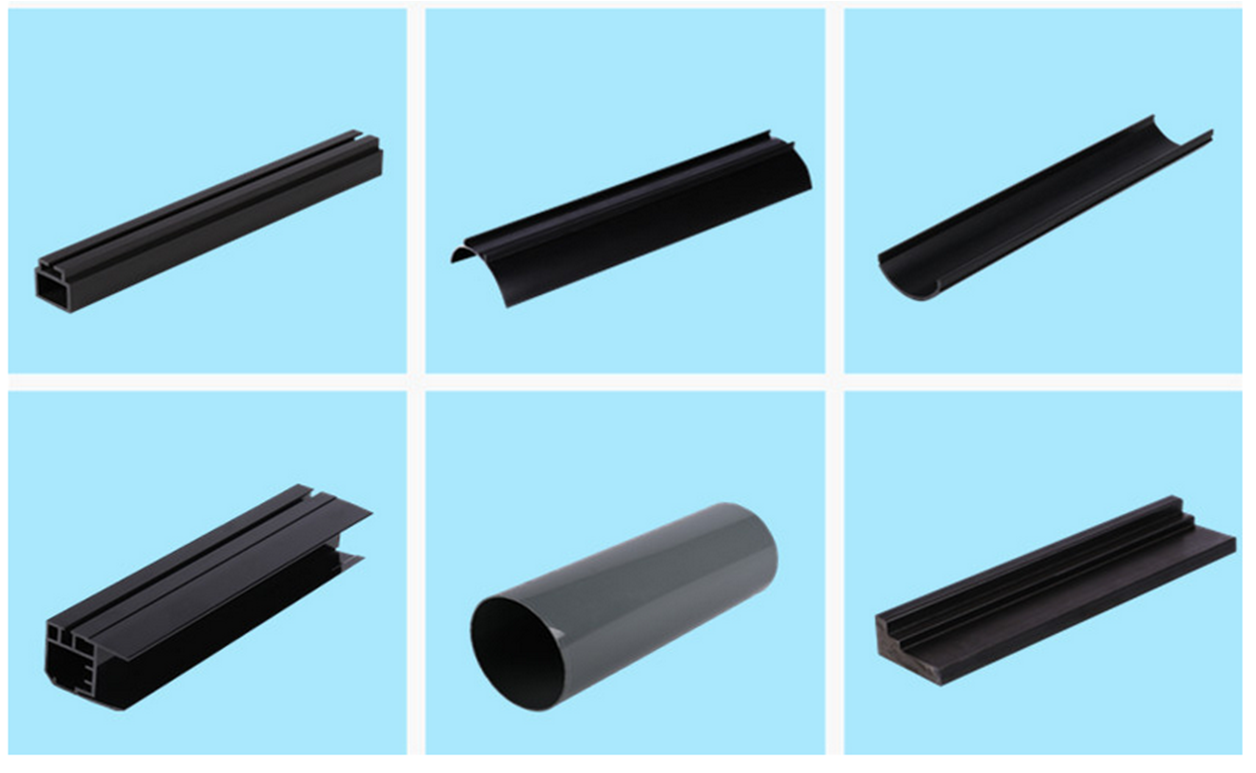

Plastic extrusion services. Our company has 4 plastic extrusion lines, and can produce 10,000m plastic ecah day.

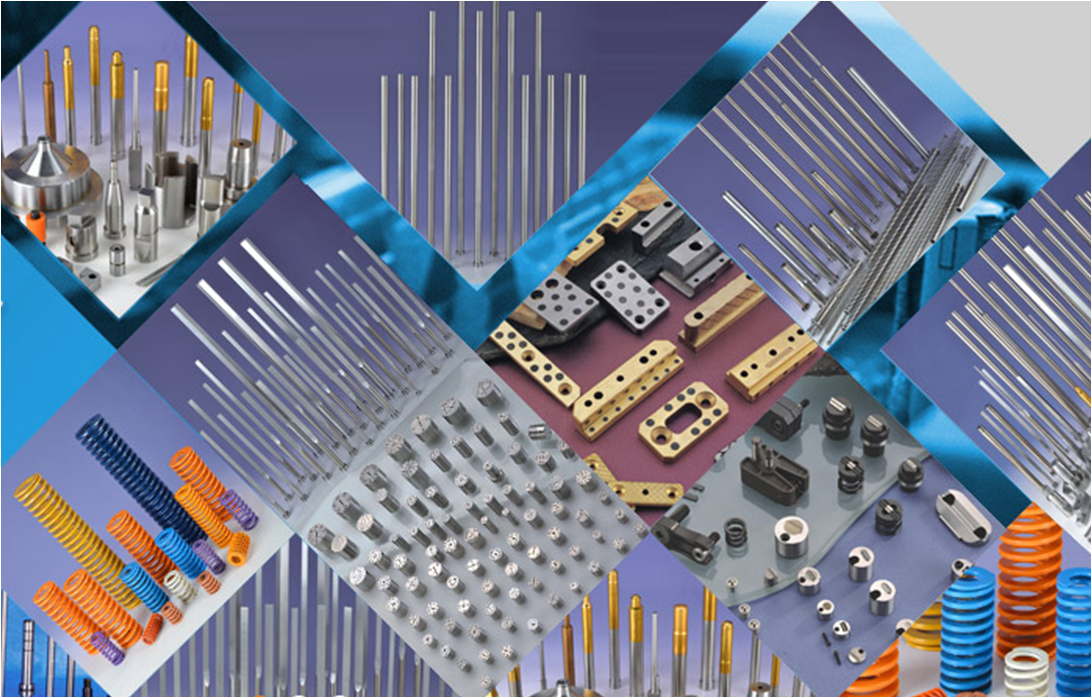

Our metal machining services include:

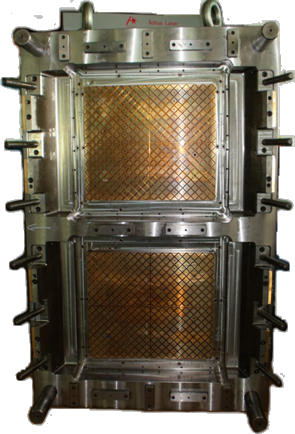

injection mold tooling,

we can produce about 15 sets injection mold tooling per month, it is from small precision molds with tight tolerance to 10 ton large molds.

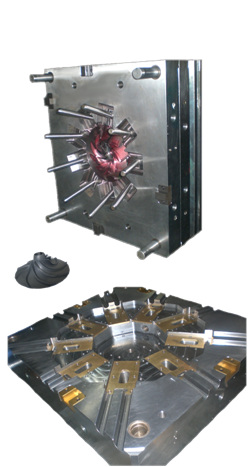

Our company is especially good at double injeciton molding,

unscrewing molds and over mold.

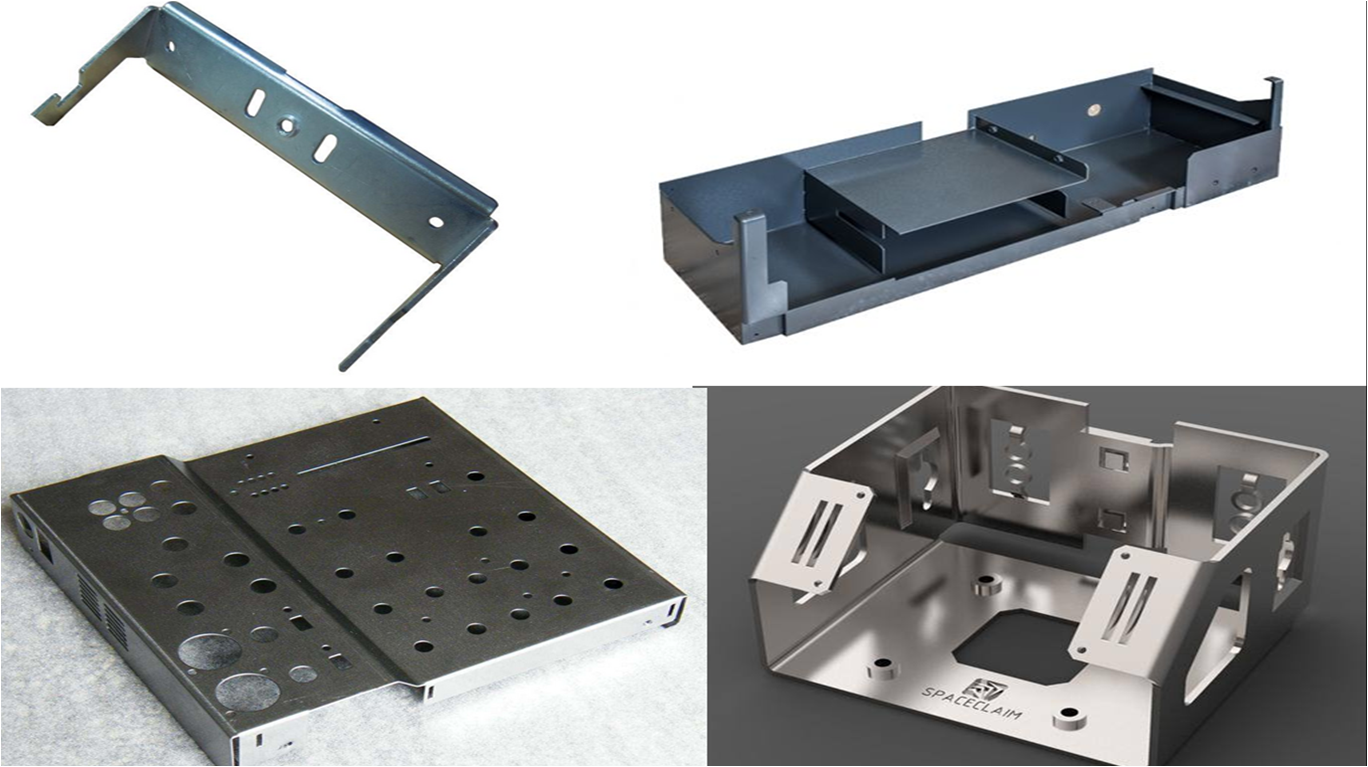

custom metal parts fabrication. Our company provides custom metal parts fabrication services.

CNC machining service. Our company provides highly precise metal machining services that includes CNC, wire EDM, polishing..

If you need highly precise components, are looking for a reliable machining supplier to reduce costs, reduce lead times,

improve quality and increase productivity, our machining services is a good choice

Aluminum casting parts. We offer aluminum casting parts, our aluminum casting molding machine is from 160 ton to 550 ton and can cast 0.01kg-2kg Aluminum casting parts.

stainless steel casting parts. We offer precise customed stainless steel casting parts, the weight of part is from 0.01kg-5kg.

sheet metal manufacturing services.

Our company has injection molding machines from 100ton to 1000ton,and 2 sets double injection molding machine.

Our experienced team of engineers work with the latest engineering tools and software to aid in increasing engineering

and manufacturing efficiency, productivity, and versatility to help you construct a quality plastic injection molds from single component to complicated tight tolerance

parts or multiple part project ,to create the best possible and cost effective mold for your project requirements.

Electric Products(like washing machine part, air condition part mold,refrigerator part mold, remote controller etc.);

Automobile Components(like bumper mold, Car Fender guard, car door, and Car lamp etc.);

Household plastics(like chair, table, toilet seat cover, bucket, plastic hanger, basket, box ,cutlery, cup, food container etc);

Printer Parts parts;

Overmold and double mold;

Others Kinds.

Our company's design team also supply plastic injection mold design services according to DME, Hasco or the customers' standard.

Leadtime usually is 3-6 days, the price is from USD$300 to USD$1200. If you are an injection mold company in

the United States or Canada, England... Our plastic injection mold tooling design services is a good choice. Don't worry about risk.

You needn't pay any cost unless you are satisfied with our design.

Viewmold provides high precise CNC machining services That include CNC machining, wire EDM machining, EDM machining.