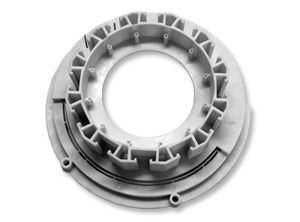

Viewmold is plastic molding and metal machining company in China,we provides the

custom plastic parts that include injection molding and

plastic extrusion for global customers.

It is a very easy job to find a injection molding company in China, but it is difficult to find a high quality injection molding supplier. Viewmold company's features:

Our company's philosophy is that good reputation is the most precious wealth, we may miss chance, we also may lost profits, but we can't lost reputation!

Pursue excellence, we go on improving our work to provide better parts for our customers.

Quality is more important than cost.

We adopt 100% fresh plastic material for injection molding.

Our injection molding room has more than 30 injection molding machines,the tons are from 100T to 1000T and 2 sets 160 TON doulbe injection molding machines.

Our injection molding department can provide more type of services:

1:simple prototyping mold,if you need just 5-50 units, the type molding solution is suitable. The lead time also is very short, it's about 10-25 days.

You also select all types plastic material.

2:low-volume production,100-10,000 units.

3: high-volume production,

4:insert molding,

5:micro-molding,

6:large-part molding, our the largest the injeciton molding machine can injection the large part the weight is more than 2kg.

7:two-shot injection molding, overmold. our team are specilists in the area

8:reel-to-reel molding

9: post machining

10:hot stamping

11:assembly

12:bonding

packaging and shipping.

What is the high quality injection molding plastic part?

1: precise and stable sizes, all sizes of all parts match tolerance request during total production cycle.

2: perfect shape, there is no any shape defects from injection mold tooling, such as: step, ejector mark, gate residual, scratch, losing features...

3: perfect appearance, there is no any injection molding defects.

4:100% fresh plastic material match request customers required.

5: reliable package and shipping.

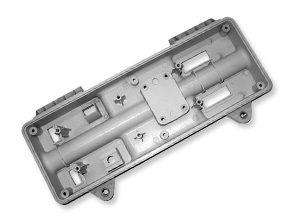

How to get high quality injection molding parts? Our company has rich experiences for achieving the purpose.

1:a good injection molding part comes from a good injection mold tooling.

Our company has a very excel professional team that is response for establishing high quality tooling.

2:reliable injection molding machines. all most our injection molding machines are new with full automatical robots.

3:excel engineers team. We havs a excel professional injection molding team that are response for soloving

injection molding issues during production.

4:thorough production management. it includes files, plastic material, parts, injeciton molding technology, injection molding machines.

5:quality management. Our QC engineers follow our quality procedures to ensure that all jobs are done right every time. Our inspection process not only includes final plastic molding parts but also aesthetics,

packaging and delivery criteria are all part of the inspection process as well.

6:clear tidy work environment.

Injection molding's features

Injection molding is an important method, which is primarily applicable to thermoplastic plastic molding; Molding can be a complex shape of precision plastic parts. At room temperature thermoplastic materials

are solid. In order to shape them they must first be heated to their molten temperature. When molten, they can then be manipulated to a new shape. When plastic molded to

their new shape they will be cooled to solidify, then part is ejected out.

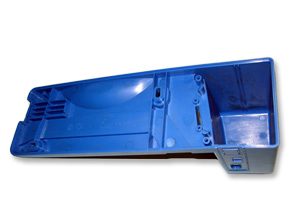

Select suitable plastic material for your parts

In terms of material capabilities, plastic molding services address considerations such as impact

strength, high and low temperature characteristics, warpage, and resistance to

ultraviolet (UV) light. Commodity grade resins are more widely used than other

graded resins and include polyethylene, polypropylene, polystyrene and polyvinyl

chloride (PVC). Engineering grade resins are more difficult to process than

other graded resins, but have characteristics that make them desirable for

specialized use. Widely used engineering grade thermoplastics include acetal,

acrylonitrile butadiene styrene (ABS), nylon, noryl and polycarbonate.