ViewMold Co Ltd is an ISO 9001:2000 certified plastic injection molds company that supplies

plastic injection molds

plastic injection molds design

plastic injection molds manufacturing of high quality,plastic injection molding...

We are Proud to bring to you the quality and speed you would expect from Viewmold plastic injection molds. We believe we will be your supplier of choice. Just give Viewmold a

email or

submit a quote online.

Our team of quote specialists is the most responsive and the most hands on.

TIGHTENING TORQUES AND THE

TORQUE-TENSION RELATIONSHIP

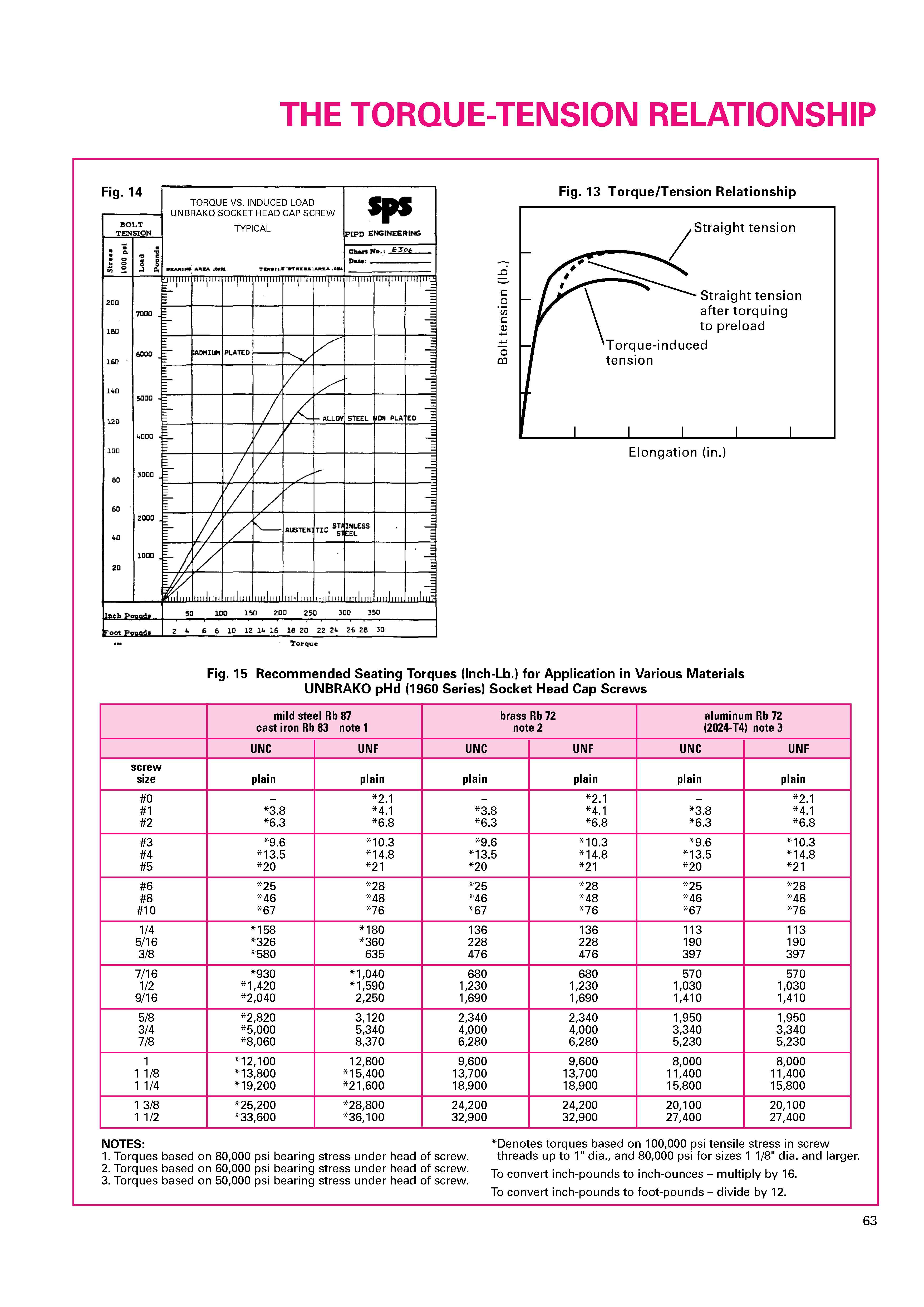

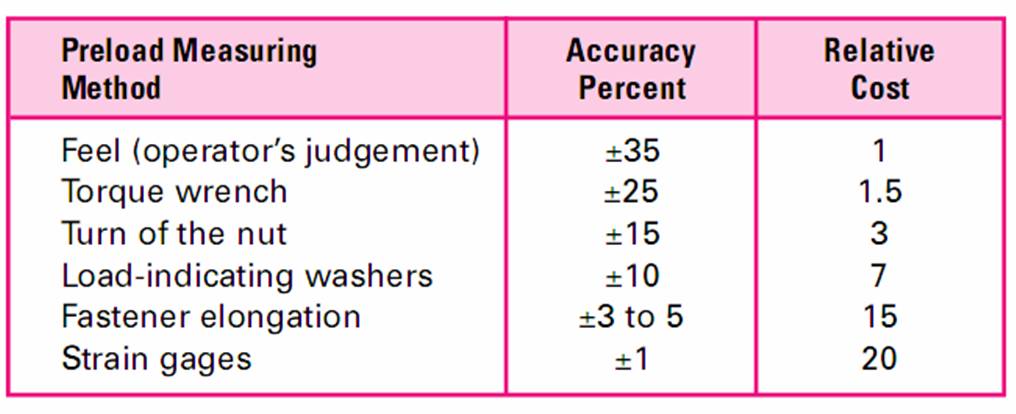

All of the analysis and design work done in advance will have little meaning if the proper preload is not achieved. Several discussions in this technical section stress the importance of preload to maintaining joint integrity. There are many methods for measuring preload (see Table 12). However, one of the least expensive techniques that provides a reasonable level of accuracy versus cost is by measuring torque. The fundamental characteristic required is to know the relationship between torque and tension for any particular bolted joint. Once the desired design preload must be identified and specified first, then the torque required to induce that preload is determined.

Within the elastic range, before permanent stretch is induced, the relationship between torque and tension is essentially linear (see figure 13). Some studies have found up to 75 variables have an effect on this relationship: materials, temperature, rate of installation, thread helix angle, coefficients of friction, etc. One way that has been developed to reduce the complexity is to depend on empirical test results. That is, to perform experiments under the application conditions by measuring the induced torque and recording the resulting tension. This can be done with relatively simple, calibrated hydraulic pressure sensors, electric strain gages, or piezoelectric load cells. Once the data is gathered and plotted on a chart, the slope of the curve can be used to calculate a correlation factor. This technique has created an accepted formula for relating torque to tension.

T = K X D X P

T = torque, lbf.-in.

D = fastener nominal diameter, inches

P = preload, lbf.

K = "nut factor", or"tightening factor", or "k-value"

If the preload and fastener diameter are selected in

the design process, and the K-value for the application

conditions is known, then the necessary torque can be

calculated. It is noted that even with a specified torque,

actual conditions at the time of installation can result in

variations in the actual preload achieved (see Table 12).

One of the most critical criteria is the selection of the

K-value. Accepted nominal values for many industrial

applications are:

K = 0.20 for as-received steel bolts into steel holes

K = 0.15 steel bolts with cadmium plating, which acts like

a lubricant,

K = 0.28 steel bolts with zinc plating.

The K-value is not the coefficient of the friction (); it is

an empirically derived correlation factor.

It is readily apparent that if the torque intended for a

zinc plated fastener is used for cadmium plated fastener,

the preload will be almost two times that intended; it

may actually cause the bolt to break.

Another influence is where friction occurs. For steel

bolts holes, approximately 50% of the installation torque

is consumed by friction under the head, 35% by thread

friction, and only the remaining 15% inducing preload

tension. Therefore, if lubricant is applied just on the

fastener underhead, full friction reduction will not be

achieved. Similarly, if the material against which the

fastener is bearing, e.g. aluminum, is different than the

internal thread material, e.g. cast iron, the effective

friction may be difficult to predict, These examples

illustrate the importance and the value of identifying

the torque-tension relationship. It is a recommend

practice to contact the lubricant manufacturer for

K-value information if a lubricant will be used.

The recommended seating torques for Unbrako

headed socket screws are based on inducing preloads

reasonably expected in practice for each type. The

values for Unbrako metric fasteners are calculated

using VDI2230, a complex method utilized extensively

in Europe. All values assume use in the received con-

dition in steel holes. It is understandable the designer

may need preloads higher than those listed. The

following discussion is presented for those cases.

Table 12

Industrial Fasteners Institute's

Torque-Measuring Method

TORSION-TENSION YIELD AND TENSION

CAPABILITY AFTER TORQUING

Once a headed fastener has been seated against a bear-

ing surface, the inducement of torque will be translated

into both torsion and tension stresses. These stresses

combine to induce twist. If torque continues to be induced,

the stress along the angle of twist will be the largest

stress while the bolt is being torqued. Consequently, the

stress along the bolt axis (axial tension) will be something

less. This is why a bolt can fail at a lower tensile stress

during installation than when it is pulled in straight tension

alone, eg . a tensile test. Research has indicated the axial

tension can range from 135,000 to 145,000 PSI for industry

socket head cap screws at torsion-tension yield, depending on diameter. Including the preload variation that can

occur with various installation techniques, eg. up to 25%,

it can be understood why some recommended torques

induce preload reasonably lower than the yield point.

Figure 13 also illustrates the effect of straight tension

applied after installation has stopped. Immediately after

stopping the installation procedure there will be some

relaxation, and the torsion component will drop toward

zero. This leaves only the axial tension, which keeps

the joint clamped together. Once the torsion is relieved,

the axial tension yield value and ultimate value for the

fastener will be appropriate.