Much has been written regarding the significance of the

notched bar impact testing of steels and other metallic

materials. The Charpy and Izod type test relate notch

behavior (brittleness versus ductility) by applying a single

overload of stress. The results of these tests provide

quantitive comparisons but are not convertible to energy

values useful for engineering design calculations. The

results of an individual test are related to that particular

specimen size, notch geometry and testing conditions

and cannot be generalized to other sizes of specimens

and conditions.

The results of these tests are useful in determining

the susceptibility of a material to brittle behavior when

the applied stress is perpendicular to the major stress.

In externally threaded fasteners, however, the loading

usually is applied in a longitudinal direction. The impact

test, therefore, which should be applicable would be one

where the applied impact stress supplements the major

stress. Only in shear loading on fasteners is the major

stress in the transverse direction.

Considerable testing has been conducted in an effort

to determine if a relationship exists between the Charpy

V notch properties of a material and the tension properties of an externally threaded fastener manufactured

from the same material.

Some conclusions which can be drawn from the

extensive impact testing are as follows:

1. The tension impact properties of externally threaded

fasteners do not follow the Charpy V notch impact pat-

tern.

2. Some of the variables which effect the tension impact

properties are:

A. The number of exposed threads

B. The length of the fastener

C. The relationship of the fastener shank diameter to

the thread area.

D. The hardness or fastener ultimate tensile strength

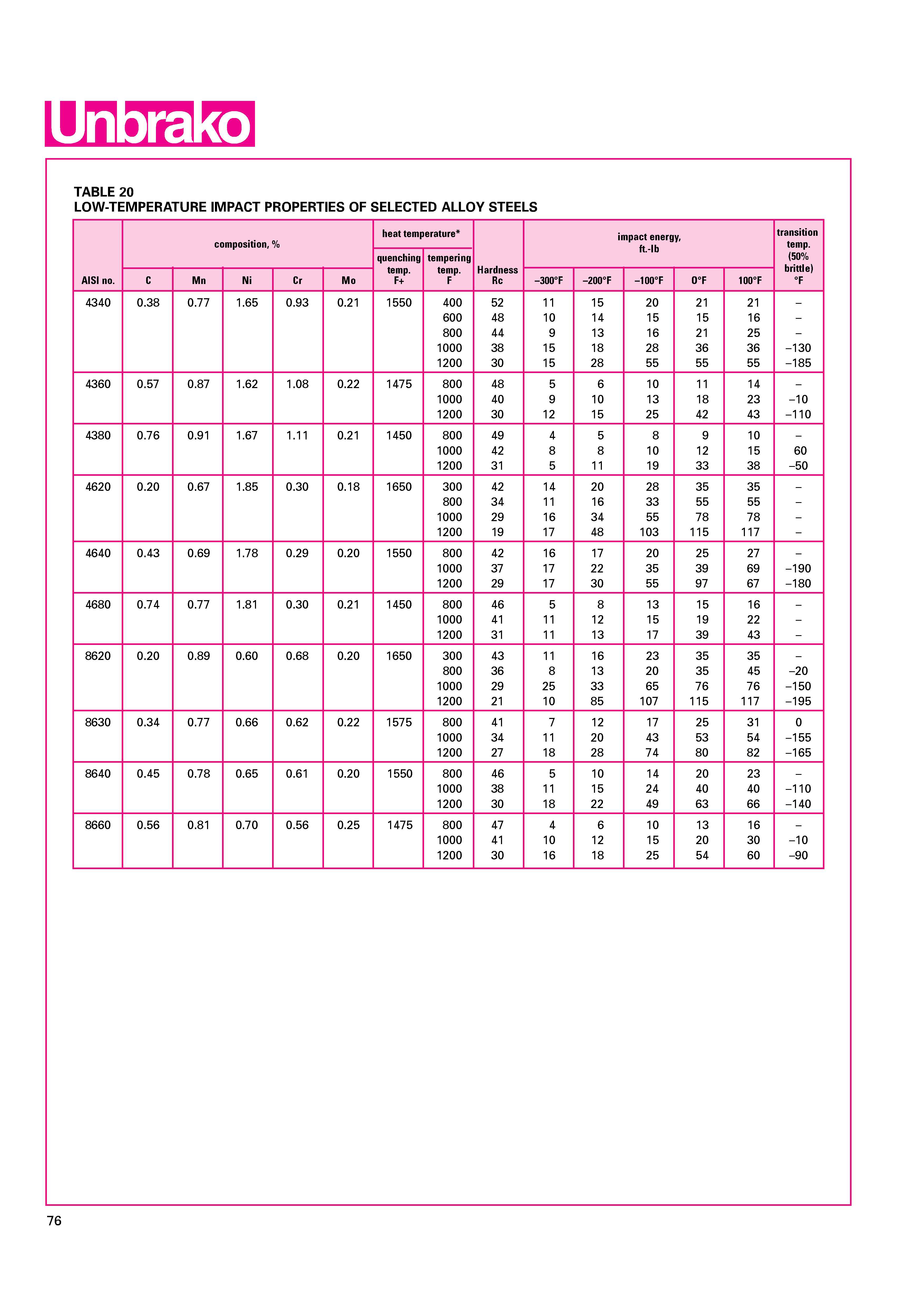

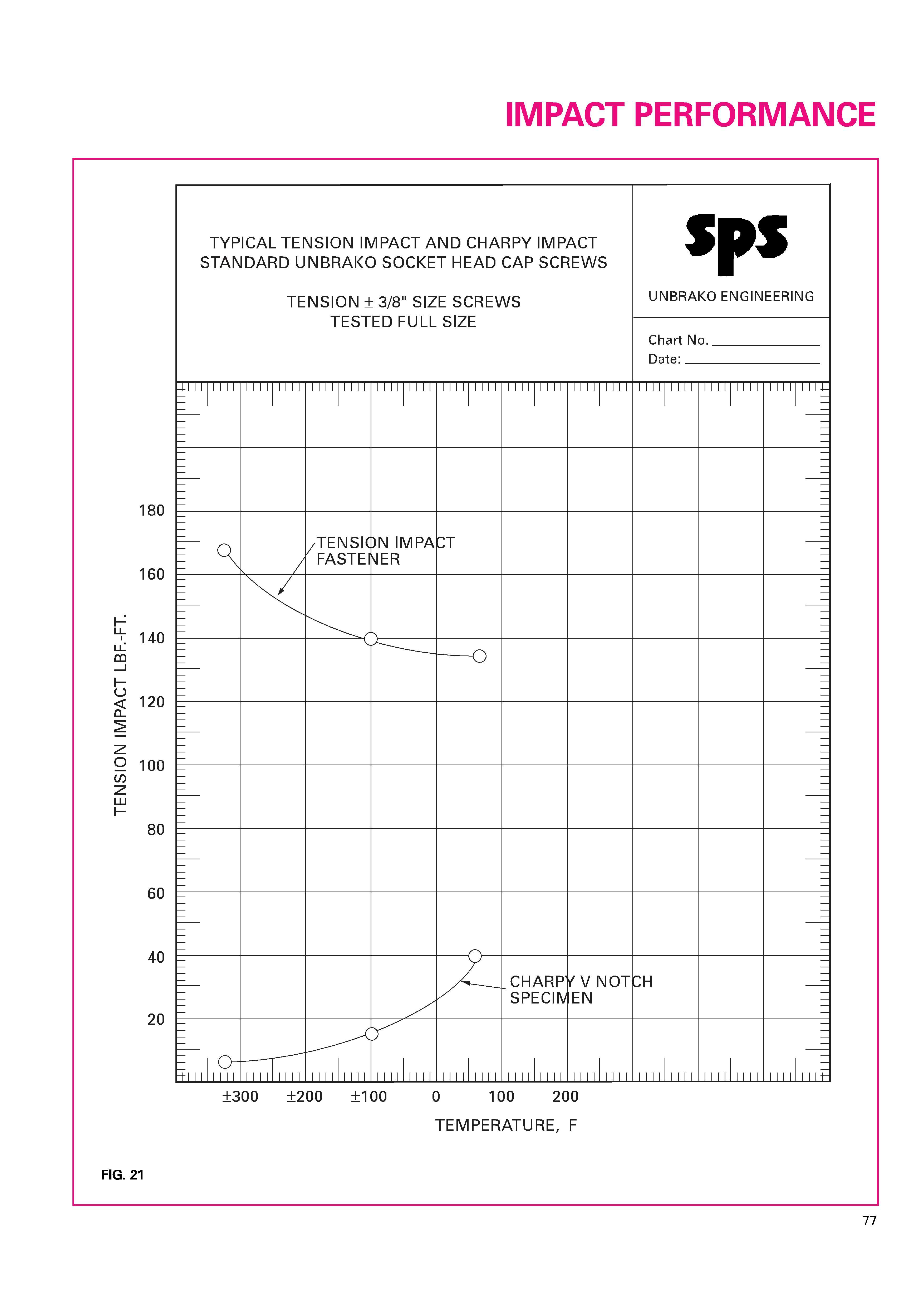

Following are charts showing tension impact versus

Charpy impact properties, the effect of strength and

diameter on tension impact properties and the effect of

test temperature.

Please note from figure 21 that while the Charpy

impact strength of socket head cap screw materials are

decreasing at sub-zero temperatures, the tension impact

strength of the same screws is increasing. This compares

favorable with the effect of cryogenic temperatures on

the tensile strength of the screws. Note the similar

increase in tensile strength shown in figure 22.

It is recommended, therefore, that less importance be

attached to Charpy impact properties of materials which

are intended to be given to impact properties for threaded

fasteners. If any consideration is to be given to impact

properties of bolts or screws, it is advisable to investigate

the tension impact properties of full size fasteners since

this more closely approximates the actual application.

Fastener Material

For Concentration-Cell Corrosion: Keep surfaces

smooth and minimize or eliminate lap joints, crevices,

and seams. Surfaces should be clean and free of organic

material and dirt. Air trapped under a speck of dirt on the

surface of the metal may form an oxygen concentration

cell and start pitting.

For maximum protection, bolts and nuts should have

smooth surfaces, especially in the seating areas. Flushhead bolts should be used where possible. Further,

joints can be sealed with paint or other sealant material.

For Fretting Corrosion: Apply a lubricant (usually oil)

to mating surfaces. Where fretting corrosion is likely to

occur: 1. Specify materials of maximum practicable hardness. 2. Use fasteners that have residual compressive

stresses on the surfaces that may be under attack. 3.

Specify maximum preload in the joint. A higher clamping

force results in a more rigid joint with less relative move-

ment possible between mating services.

For Stress Corrosion: Choose a fastener material that

resists stress corrosion in the service environment.

Reduce fastener hardness (if reduced strength can be

tolerated), since this seems to be a factor in stress

corrosion.

Minimize crevices and stress risers in the bolted joint

and compensate for thermal stresses. Residual stresses

resulting from sudden changes in temperature accelerate

stress corrosion.

If possible, induce residual compressive stresses into

the surface of the fastener by shot-peening or pressure

rolling.

For Corrosion Fatigue: In general, design the joint

for high fatigue life, since the principal effect of this form

of corrosion is reduced fatigue performance. Factors

extending fatigue performance are: 1. Application and

maintenance of a high preload. 2. Proper alignment to

avoid bending stresses.

If the environment is severe, periodic inspection is

recommended so that partial failures may be detected

before the structure is endangered.

As with stress and fretting corrosion, compressive

stresses induced on the fastener surfaces by thread

rolling, fillet rolling, or shot peening will reduce corrosion

fatigue. Further protection is provided by surface coating.

TYPES OF CORROSION

Direct Attack°most common form of corrosion affecting

all metals and structural forms. It is a direct and general

chemical reaction of the metal with a corrosive mediumliquid, gas, or even a solid.

Galvanic Corrosion°occurs with dissimilar metals contact.

Presence of an electrolyte, which may be nothing more

than an individual atmosphere, causes corrosive action

in the galvanic couple. The anodic, or less noble material,

is the sacrificial element. Hence, in a joint of stainless

steel and titanium, the stainless steel corrodes. One of

the worst galvanic joints would consist of magnesium

and titanium in contact.

Concentration Cell Corrosion°takes place with metals in

close proximity and, unlike galvanic corrosion, does not

require dissimilar metals. When two or more areas on

the surface of a metal are exposed to different concentrations of the same solution, a difference in electrical

potential results, and corrosion takes place.

If the solution consists of salts of the metal itself, a metal-

ion cell is formed, and corrosion takes place on the sur-

faces in close contact. The corrosive solution between

the two surfaces is relatively more stagnant (and thus

has a higher concentration of metal ions in solution) than

the corrosive solution immediately outside the crevice.

A variation of the concentration cell is the oxygen cell in

which a corrosive medium, such as moist air, contains

different amounts of dissolved oxygen at different points.

Accelerated corrosion takes place between hidden

surfaces (either under the bolt head or nut, or between

bolted materials) and is likely to advance without

detection.

Fretting°corrosive attack or deterioration occurring

between containing, highly-loaded metal surfaces sub-

jected to very slight (vibratory) motion. Although the

mechanism is not completely understood, it is probably

a highly accelerated form of oxidation under heat and

stress. In threaded joints, fretting can occur between

mating threads, at the bearing surfaces under the head

of the screw, or under the nut. It is most likely to occur in

high tensile, high-frequency, dynamic-load applications.

There need be no special environment to induce this

form of corrosion...merely the presence of air plus vibra-

tory rubbing. It can even occur when only one of the

materials in contact is metal.

Stress Corrosion Cracking°occurs over a period of time

in high-stressed, high-strength joints. Although not fully

understood, stress corrosion cracking is believed to be

caused by the combined and mutually accelerating

effects of static tensile stress and corrosive environment.

Initial pitting somehow tales place which, in turn, further

increases stress build-up. The effect is cumulative and, in

a highly stressed joint, can result in sudden failure.

Corrosion Fatigue°accelerated fatigue failure occurring

in the presence of a corrosive medium. It differs from

stress corrosion cracking in that dynamic alternating

stress, rather than static tensile stress, is the contributing

agent.

Corrosion fatigue affects the normal endurance limit of

the bolt. The conventional fatigue curve of a normal bolt

joint levels off at its endurance limit, or maximum

dynamic load that can be sustained indefinitely without

fatigue failure. Under conditions of corrosion fatigue,

however, the curve does not level off but continues

downward to a point of failure at a finite number of

stress cycles.