NX CMM Inspection Programming is based on the NX Manufacturing architecture and offers many flexible ways to inspect a model. Although you can complete many tasks in different orders, the following represents a typical workflow.

-

Open an NX work part file to inspect and optionally, create tolerances and annotations in PMI.

-

Create an inspection file that references the NX work part file.

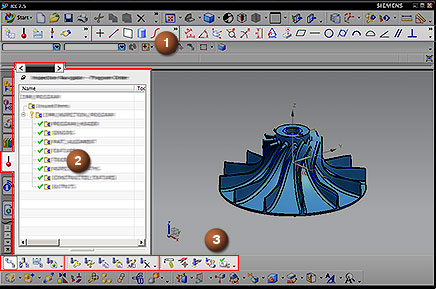

Insert, Feature, and Tolerance toolbars

Inspection Navigator

Navigator, Actions, and Operations toolbars

-

Retrieve a virtual CMM model, probe head, and probe from a library, and align the work part file as necessary.

-

Link to PMI to import:

-

Inspection features for all toleranced solids, based upon model geometry.

-

GD&T and direct tolerance information.

-

Automatic inspection paths on the toleranced features.

Note:

Any tolerance and feature names you define in PMI are retained in NX CMM Inspection Programming.

-

-

Add additional objects, including:

-

Features, such as points, lines, planes, cylinders, curves, surfaces, patterns, arcs, circles, spheres, cones, closed and open slots and tabs, and tori.

-

Tolerances, including:

-

Direct tolerances such as distance between, angle between, coordinate, diameter, radius, width, and cone angle.

-

Datum definitions and most GD&T tolerances.

-

-

Special features and inspection paths.

Constructed features

Inspection paths

Multi-feature paths

-

-

Calibrate and simulate your processes using NX collision detection.

-

Output your processes to a Dimensional Measuring Interface Standard (DMIS) file and then run the program on an actual CMM.

-

In a solution such as Dimensional Planning and Validation (DPV), statistically compare the results file created from your inspection run to the NX CMM Inspection Programming process.

-

Edit your process if necessary. You can delete, modify, or add new features, tolerances, probes, and inspection operations.